ASU builds ML to supercompute melting points for any compound

If you apply enough heat to a material, at some point, most things melt, just like ice cream on a hot summer day.

Engineers rely on this knowledge daily. Knowing the exact melting temperatures is a critical parameter for building any high-performance materials. From the building and safety of bridges to gas turbines and jet engines to heat shields on aircraft, all are dependent on knowing the performance limits of materials. Materials are often synthesized or processed employing the molten or liquid state, so knowing melting is critical to making new materials.

Shift to the field of Earth and planetary science, and the melting points are used to reveal clues into Earth’s past and the characteristics of planets in our solar system and far-out orbiting exoplanets.

But measuring the melting temperature of a compound or material is an arduous task. That’s why, of the estimated 200,000-plus inorganic compounds, less than 10% of their melting temperatures are known.

Melting temperatures are often measured after carefully calibrating crystal structures or plotting the thermodynamic free energy curves when a material melts, creating a phase change from a solid to a liquid. This is analogous to the melting of solid ice to form liquid water. But when high-temperature materials exceed 2,000 or 3,000 degrees, finding an experimental chamber to do the measurements can be a challenge. And sometimes, rocks have complex mixtures of minerals not much larger than a grain of sand----so getting enough samples of a single mineral can also present a challenge. Materials synthesized under extreme conditions of high pressure and temperature are also often available in only very small amounts.

Now, Arizona State University researchers Qi-Jun Hong, Alexandra Navrotsky, and Sergey Ushakov, together with Axel van de Walle at Brown University have harnessed the power of artificial intelligence (AI), or machine learning (ML), to demonstrate an easier way to predict melting temperatures for potentially any compound or chemical formula.

“We employ machine learning methods to fill this gap by building a rapid and accurate mapping from chemical formula to melting temperature,” said Hong, assistant professor in the School for Engineering of Matter, Transport, and Energy, within the Ira A. Fulton Schools of Engineering.

“The model we have developed will facilitate large-scale data analysis involving melting temperature in a wide range of areas. These include the discovery of new high-temperature materials, the design of novel extractive metallurgy processes, the modeling of mineral formation, the evolution of Earth over geological time, and the prediction of exoplanet structure.”

Hong’s approach allows melting temperatures to be computed in milliseconds for any compound or chemical formula input. To do so, the research team built a model from an architecture of neural networks and trained their machine learning program on a custom-curated database encompassing 9375 materials, out of which 982 compounds have melting temperatures higher than a scorching 3100 degrees Fahrenheit (or 2000 degrees Kelvin). Materials at this temperature glow white-hot.

Hong used this methodology to explore two lines of research: 1) predicting the melting temperatures of nearly 5,000 minerals and 2) finding new materials that have extremely high melting temperatures above 3000 Kelvin (or 5000 degrees Fahrenheit).

For the minerals project, Hong’s team was able to predict melting temperatures and correlate these with the known major geological epochs of Earth’s history. These AI-garnered melting temperatures were applied to minerals made since the formation of Earth about 4.5 billion years ago. The oldest minerals originate directly from stars or interstellar and solar nebula condensates predating Earth’s formation 4.5 billion years ago. These are the most refractory, with melting temperatures around 2600 F.

For the most part, there was a gradual decrease in the calculated melting temperatures of minerals identified on Earth in more recent time, with 2 major exceptions.

“The gradual overall decrease in the melting temperature of minerals formed during Earth history is interrupted with two anomalies, which are distinctly pronounced in average and medium melting temperatures using 250 or 500 million years ago binning,” said Navrotsky, an ASU Professor with joint faculty appointments in the School of Molecular Sciences and School for Engineering of Matter, Transport and Energy and Director of MOTU, the Navrotsky Eyring Center for Materials of the Universe.

The first anomaly in Earth’s early history came from a dramatic temperature spike caused by a scary and dynamic time of major meteor strikes, including the possible formation of the Moon.

“The spike at 3.750 billion years ago correlates to the proposed timing of late-heavy bombardment, hypothesized exclusively from dating of lunar samples and currently debated,” said Navrotsky.

The team also noticed a large temperature dip in the melting temperatures of minerals around 1.75 billion years ago.

“The dip at 1.750 billion years ago is related to the first known occurrences of a large number of hydrous (water-containing) minerals and correlates with the Huronian glaciation, the longest ice age thought to be the first time Earth was completely covered in ice.”

With their machine learning program trained to successfully replicate mineral melting in Earth’s early history, next, the team turned their attention to finding new materials that have extremely high melting temperatures. Dozens of new materials are identified and computationally predicted to have extremely high melting temperatures above 5,000 degrees Fahrenheit (3000 Kelvin), more than half the temperature of the Sun’s surface.

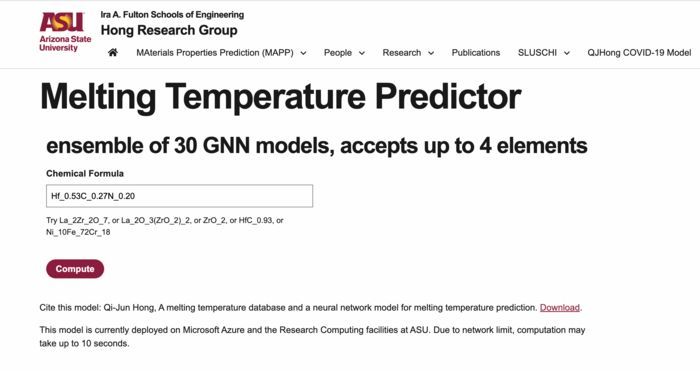

The team made their model simple and reliable enough that any user can obtain the melting temperature within seconds for any compound based only on its chemical formula.

“To use the model, a user needs to visit the webpage and input the chemical compositions of the material of interest,” said Hong. “The model will respond with a predicted melting temperature in seconds, as well as the actual melting temperatures of the nearest neighbors (i.e., the most similar materials) in the database. Thus, this model serves as not only a predictive model but a handbook of melting temperature as well.”

The model is now publicly available on the ASU webpage: https://faculty.engineering.asu.edu/hong/melting-temperature-predictor/.

The research is supported by U.S. National Science Foundation under Collaborative Research Awards DMR-2015852, 2209026 (ASU) and DMR-1835939, 2209027 (Brown University). The research team was led by Alexandra Navrotsky (Principal Investigator), Professor in SMS and SEMTE (ASU), Qi-Jun Hong, Assistant Professor in SEMTE School of Engineering (ASU), Sergey Ushakov, Research Professor in SMS (ASU), and Axel van de Walle, Professor at Brown University.

How to resolve AdBlock issue?

How to resolve AdBlock issue?