Russian scientists develop a neural network algorithm that predicts Arrhenius crossover temperature with 90 percent accuracy

A joint paper by the Department of Computational Physics and Modeling of Physical Processes and Udmurt Federal Research Center of the Russian Academy of Sciences saw light in Materials.

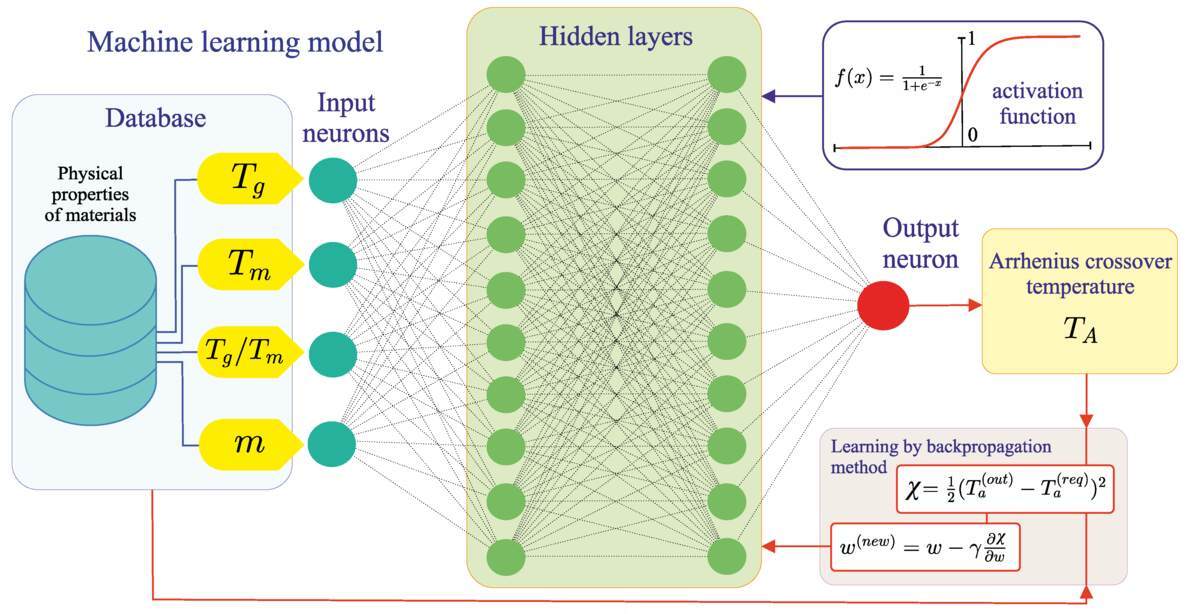

The algorithm can help speed up the production of many materials, including metal alloys, and simplify quality control during such production. An algorithm based on a neural network created at KFU makes it possible to accurately calculate the Arrhenius temperature from several physical parameters of the material.

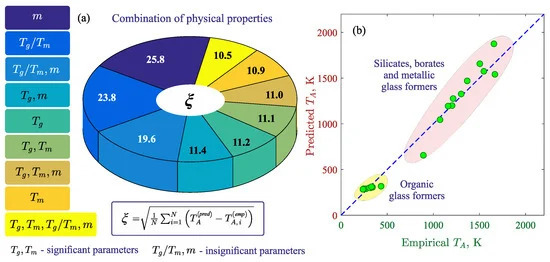

Among the parameters used by the team for modeling were melting temperature, glass transition temperature, and brittleness value. They are used to describe phase transitions and structural changes in liquids during cooling.

Co-author, Associate Professor Bulat Galimzyanov comments, “Many solid materials, such as glass, metals, plastics, initially have the form of melts – they are viscous liquids that solidify at a certain temperature, turning into a solid state. The temperature at which a change in the state of aggregation begins is called the Arrhenius temperature. When approaching it, the atoms of matter begin to move in groups and more slowly than before. This indicates the preparation of the liquid for solidification.”

The algorithm was tested for metallic, silicate, borate, and organic glasses, according to the interviewee, “We found out that for the created neural network, the melting and glass transition temperatures of the material are significant and sufficient characteristics for estimating the Arrhenius temperature. From these two values, the algorithm determined the Arrhenius temperature for all analyzed liquids with an accuracy of more than 90 percent.”

The scientists worked out an equation linking the Arrhenius temperature with the melting temperatures and the glass transition temperature.

“Glass transition and melting temperatures are easily measured in lab conditions. Furthermore, they can be found in the literature. Thus, determining the Arrhenius temperature has now become easier. We can analyze the properties of liquids faster and estimate the characteristics of resulting solid materials more precisely,” concludes Galimzyanov.

The team further plans to adapt the created algorithm to more complex materials, such as polymers.

How to resolve AdBlock issue?

How to resolve AdBlock issue?