KIST develops tech to store, manipulate electronic states in quantum dots that are smaller than 10 nm, ushering in the era of light-powered multi-level memories

Researchers from the Korea Institute of Science and Technology (KIST) and the Daegu Gyeongbuk Institute of Science and Technology (DGIST) have successfully developed a new semiconductor material that can store and manipulate electronic states in quantum dots measuring 10 nanometers or less. This new material makes it possible to store and manipulate data using light, rather than electrical signals, between the computing and storage components of a multi-level computer, thereby significantly enhancing processing speed. The development of this new multi-level optical memory device is expected to contribute towards accelerating the industrialization of next-generation system technologies, such as artificial intelligence systems.

We are facing an overwhelming amount of data. The data centers that store and process this data consume a lot of electricity, which is a major contributor to environmental pollution. To overcome this issue, researchers are exploring polygonal computing systems that have lower power consumption and higher computation speed. However, these systems are unable to handle the huge demand for data processing as they operate with electrical signals, similar to conventional binary computing systems.

Recently, the Korea Institute of Science and Technology (KIST) announced that Dr. Do Kyung Hwang of the Center for Opto-Electronic Materials & Devices and Professor Jong-Soo Lee of the Department of Energy Science & Engineering at Daegu Gyeongbuk Institute of Science and Technology (DGIST) have jointly developed a new semiconductor artificial junction material that can power next-generation memory with light. Transmitting data between the computing and storage parts of a multi-level computer using light instead of electrical signals can significantly increase processing speed.

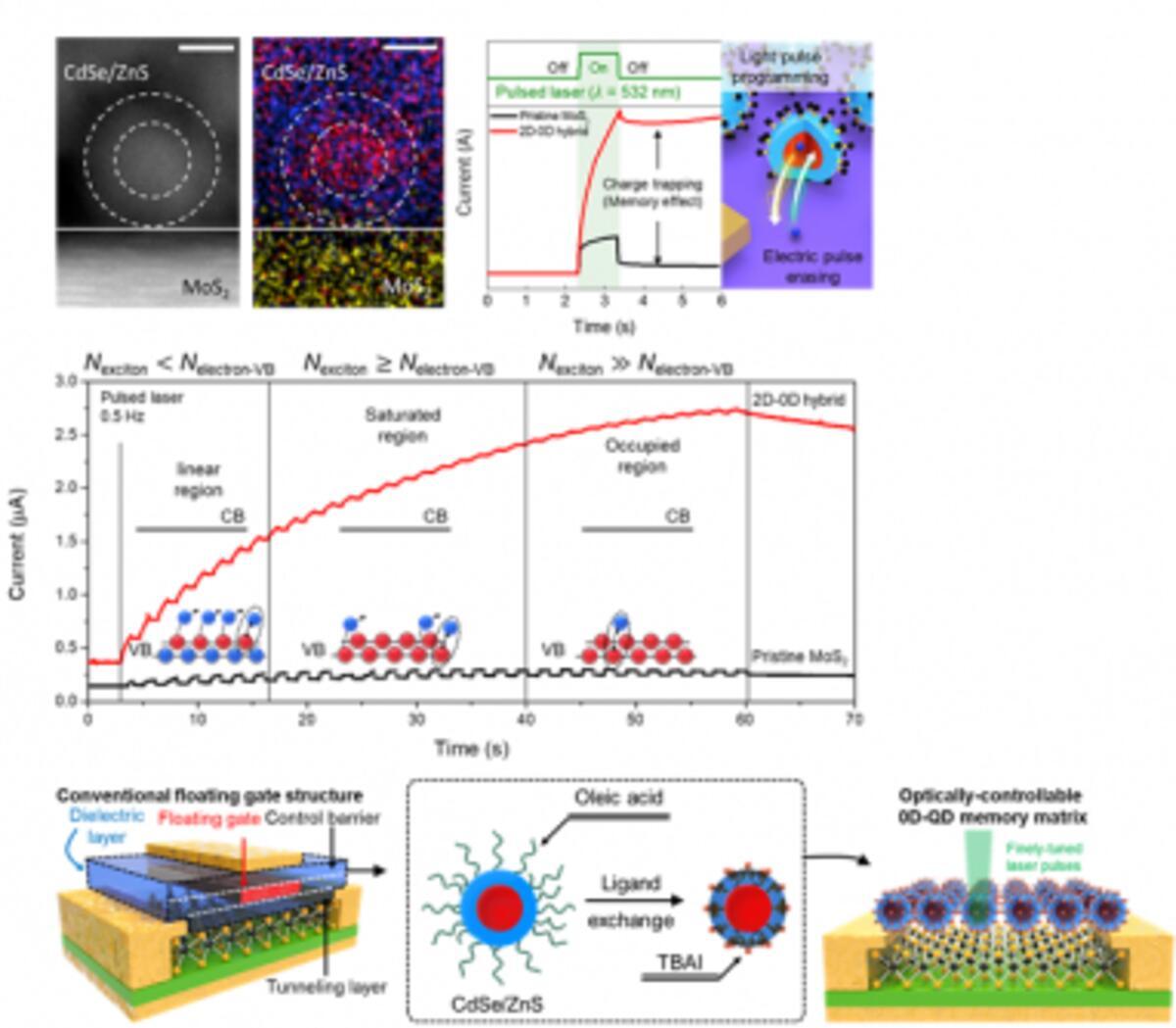

The research team has created a new semiconductor artificial junction material by joining quantum dots in a core-shell structure with zinc sulfide (ZnS) on the surface of cadmium selenide (CdSe) and a molybdenum sulfide (MoS2) semiconductor. The new material enables the storage and manipulation of electronic states within quantum dots measuring 10 nm or less.

When light hits the cadmium selenide core, some electrons flow out of the molybdenum sulfide semiconductor, trapping holes in the core and making it conductive. The electron state inside cadmium selenide is also quantized. Intermittent light pulses trap electrons in the electron band one after the other, causing a change in the resistance of the molybdenum sulfide through the field effect. The resistance changes cascade depending on the number of light pulses, allowing for more than 0 and 10 states to be maintained, unlike conventional memory which only has 0 and 1 states. The zinc sulfide shell also prevents charge leakage between neighboring quantum dots, allowing each single quantum dot to function as a memory.

Unlike quantum dots in conventional 2D-0D semiconductor artificial junction structures that amplify signals from light sensors, the team's quantum dot structure perfectly mimics the floating gate memory structure, confirming its potential for use as a next-generation optical memory. The researchers verified the effectiveness of the polynomial memory phenomenon with neural network modeling using the CIFAR-10 dataset and achieved a 91% recognition rate.

Dr. Hwang of KIST says that this new multi-level optical memory device will contribute to accelerating the industrialization of next-generation system technologies such as artificial intelligence systems. These systems have been difficult to commercialize due to technical limitations arising from the miniaturization and integration of existing silicon semiconductor devices.

POPULAR

- NASA predicts the Sun's corona behavior, revealing its mysteries using advanced computational methods

- Australia on track for unprecedented, decades-long megadroughts: Supercomputer modeling raises concern

- Revolutionizing precision agriculture: The impact of Transformer Deep Learning on water, energy demands

How to resolve AdBlock issue?

How to resolve AdBlock issue?